FQC

FQC – Fastener Quality Center – is a quality testing facility located in Shanghai, P.R. China. The laboratory is specialized in testing industrial fasteners.

The company was founded in September 2007 as a joint venture. Since then, it has been used as a quality assurance system in the heart of the Asian procurement market and managed autonomously. The companies Lederer and Fastbolt are joint-venture partners with equal rights and shareholders in FQC.

For many years, both Lederer and Fastbolt have been among the leading suppliers of fasteners in their respective areas in European commerce. Both have long experience in global procurement and its associated quality requirements.

Shareholders

Since 1982, Fastbolt has been established as a competitive supplier of industrial fasteners to the European distribution market. Fastbolt operates as a mass importer of a comprehensive range of products, sourced predominantly from the Far East, which are stocked in both Germany and the UK and subsequently supplied to a large network of distributors throughout Europe. A continual presence in the global sourcing and European distribution markets enables Fastbolt to supply high quality products at highly competitive pricing whilst offering a wide range of services which provide measurable added value to the customer.

For almost 50 years, Lederer has been one of the leading suppliers of high-quality, stainless steel fasteners and of efficient C-parts management. Normed and standardized parts, special parts and special materials constitute the basis of Lederer’s broad-based product assortment. These are supplemented by process-optimised procurement using C-parts management and Kanban systems, which ever-increasing numbers of Lederer customers are now utilising. The testing laboratory FQC in Shanghai, which locally monitors the quality of the suppliers to the Far Eastern market, rounds off the spectrum.

Team

EN

Eric Ni

General Manager

+86 (0)21 5190 5281

info@fqc-shanghai.com

Tom Hou

Operations Director

+86 (0)21 5190 5281-108

tom.hou@fqc-shanghai.com

Maggie Zhang

Senior Inside Sales

+86 (0)21 5190 5281-0

maggie.zhang@fqc-shanghai.com

Vicky Ji

Customer Service

+86 (0)21 5190 5281 101

vicky.ji@fqc-Shanghai.com

Willen Xu

QC

+86 (0)21 5190 5281 106

wei.xu@fqc-shanghai.com

Inspectors

Quality Inspectors

+86 (0)21 5190 5281

info@fqc-shanghai.com

Seth Feng

QC Engineer

+86 (0)21 5190 5281

info@fqc-shanghai.com

Lily Yang

Cashier

+86 (0)21 5190 5281

info@fqc-shanghai.com

Yeli Shi

Office Clerk

+86 (0)21 5190 5281-102

Yeli.shi@fqc-shanghai.com

Markus Rickeshenrich

Quality Supervisor

+86 (0)21 5190 5281

info@fqc-shanghai.com

Jörg Baumann

Quality Supervisor

+86 (0)21 5190 5281

info@fqc-shanghai.com

Service

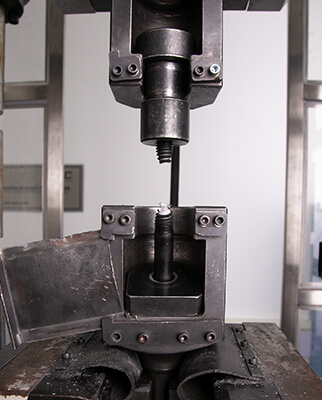

Mechanical – technological tests

Tensile tests

Tensile testing machine (200kN / 1000kN)

- Tensile test for full-size bolts or machined test pieces

- Tensile test under wedge loading of finished bolts and screws

- Proof load test for nuts

- Determination of lower yield strength or stress at 0,2 % non-proportional elongation

- Determination of elongation or reduction of area after fracture

- Bending test

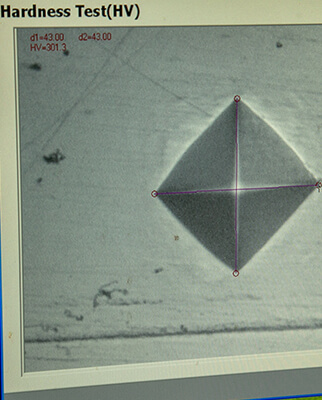

Hardness test

Hardness tester Rockwell (HRB, HRC) and Vickers (HV0,1 – HV30)

- Determination of surface hardness

- Determination of core hardness

- Hardness profile test

- Determination of case hardness depth (CHD)

- Determination of de-/carburization for bolts

Impact test

Automatic impact testing machine with max. 450 Joule

- Impact test (max -110° Celsius)

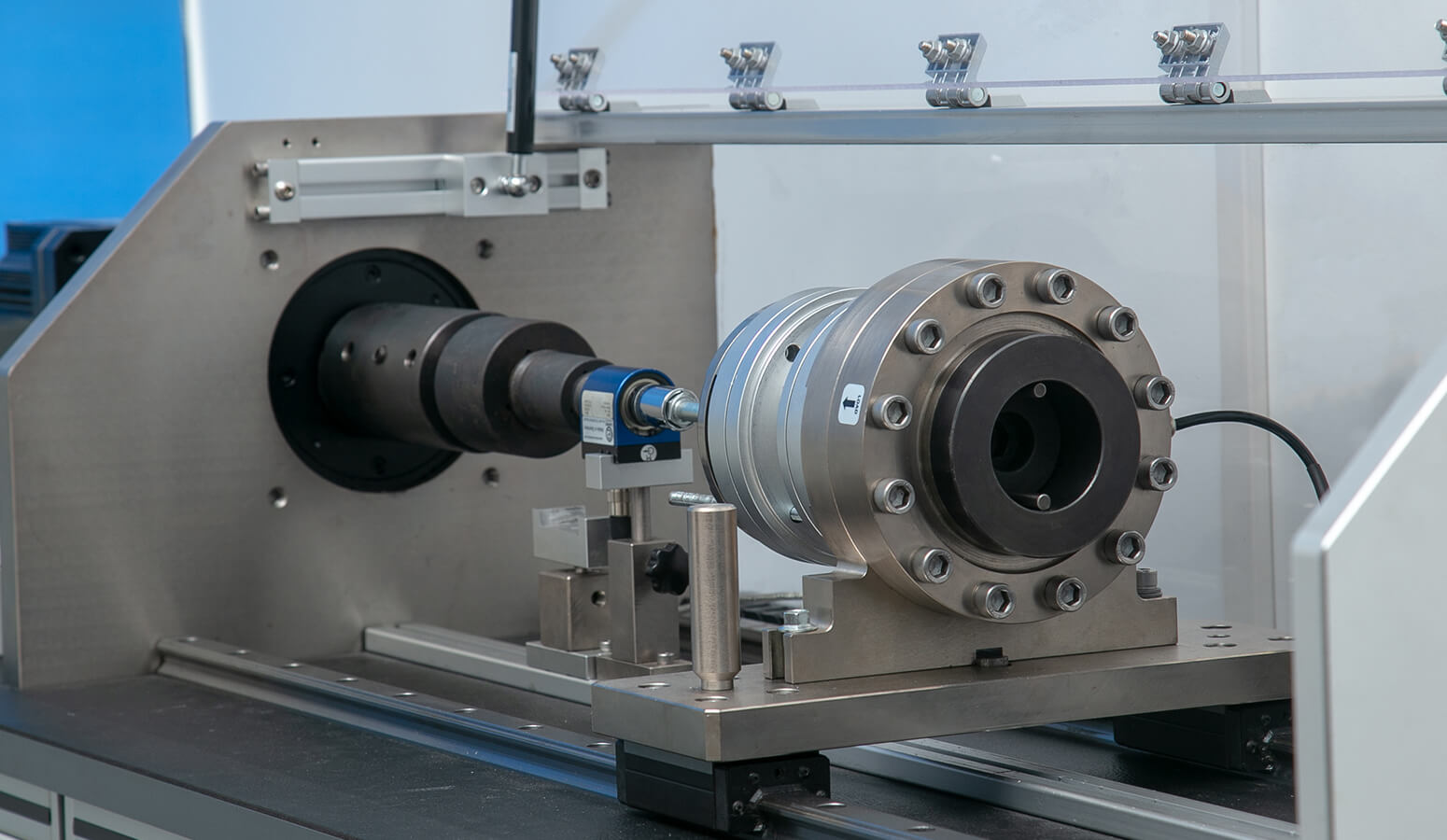

Torsion tests

Torsion inspection machine (2000Nm)

- Torque test

- Drive-in torque test

- Function test of adhesive or locking coatings

- Function test on locking nuts

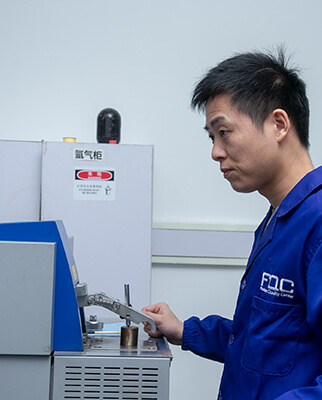

Analytical tests

Material analysis

ARC/SPARK optical emission spectrometry (OES) Analyzer

- Elements: C, Si, Mn, P, S, Ni, Cr, Cu, Mo, Al, V, Ti, B

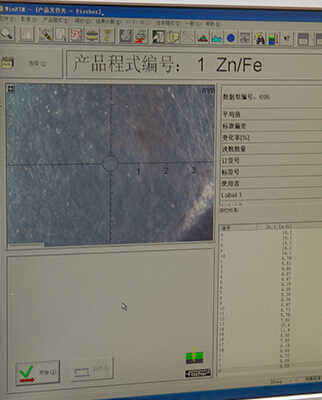

Coating thickness tests

X-ray fluorescence, magnet-inductive or microscopic method for coatings like:

- Zn/Fe (0-35µm), Ni/Fe (0-20µm), NiZn/Fe (0-25µm), Cu/Fe (0-20µm)

- Hot dip galvanized

- Zinc flake coating

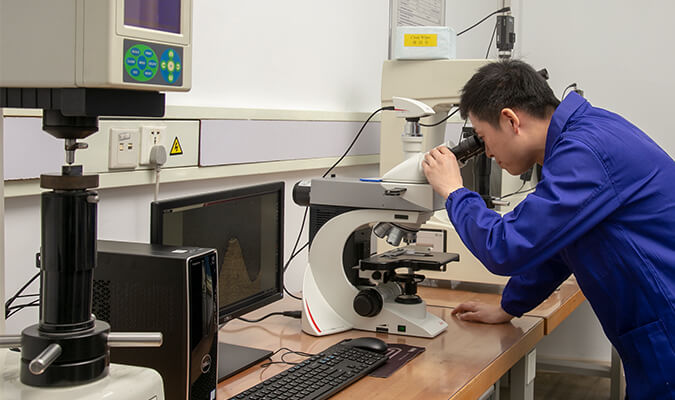

Structural examination by microscope

reflected-light microscope

- Structural examination by microscope

- Determination of De-/carburization for bolts

Function tests

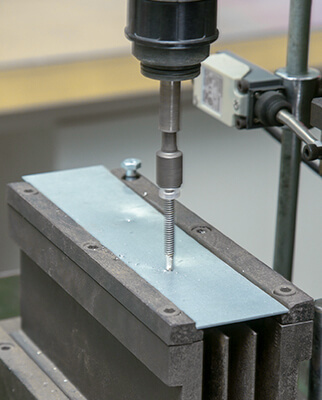

Drill speed test

- Function test for self-drilling screws

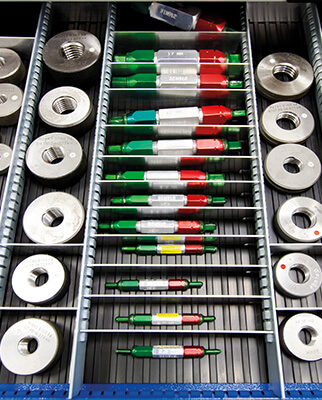

Dimensional- and tolerance tests

Dimensional and true to gauge inspections

- Fully automated dimensional inspection for length, radius, angle…

- Inspection of straightness (bending) of fasteners

- Determination of head height on screws

- Determination of recess depth

- Test with thread ring gauge Go/No Go

- Test with thread plug gauge Go/No Go

- Roughness test

Other inspections

-

Determination of corrosion resistance (NSS)

-

Head soundness test

Supplier Audit

Supplier Audit

We also visit external suppliers and carry out on-site audits and pre-shipment inspections.

Quality

In order to comply with our customers requirements we set high standards for our entire inspection activity. This includes ongoing training programs for our staff, on-time maintenance and calibration of our inspection equipment and the optimisation of our internal processes aiming to always meet customer set completion deadlines. The independent certification authority CNAS (China National Accreditation Service) has approved this competence for FQC by accrediting our laboratory according to ISO 17025:2017.

Herefore the following documents are available:

Contact

Send us your request with our contact form. We will reply as soon as possible.